Making Busan the World's Best AI Port.

Deep Reinforcement Learning-based T-CAG Port Optimization Platform

Deep Reinforcement Learning-based T-CAG Port Optimization Platform

Busan Port is a world-class transshipment hub, but Container Rehandling and Yard Congestion cause massive annual OPEX leakage.

T-CAG (Terminal Capacity And Gain) platform eliminates terminal inefficiencies through AI and generates OPEX savings.

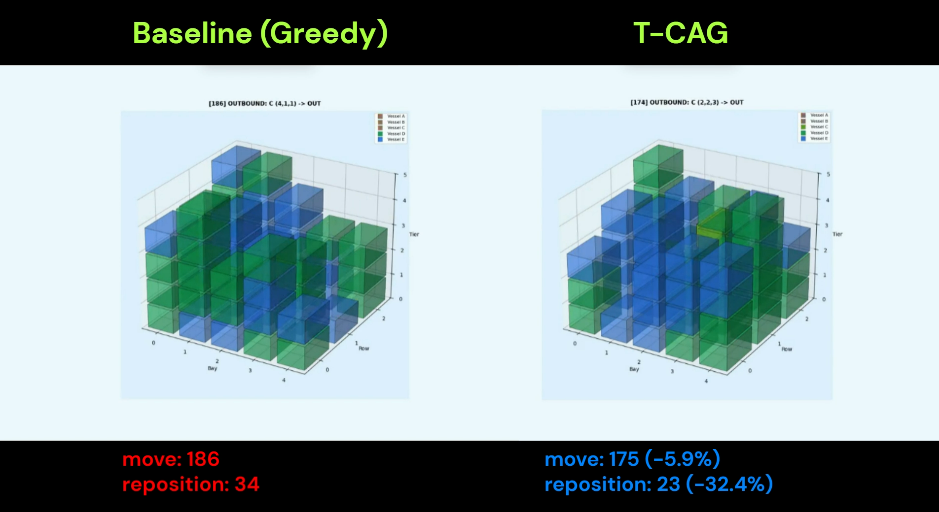

Container Rehandle Minimization AI. Reduces unnecessary rehandling operations, a core challenge in terminal operations, to cut OPEX.

Like a 'Lego Block Sorting Problem', it analyzes container departure priorities to determine optimal stacking positions so that containers leaving first are not buried underneath.

Instead of just considering current positions, it uses an AI decision-making approach (Cost Function) that predicts future costs (rehandle penalties) to prevent unnecessary work in advance.

32.4% rehandling reduction proven in 3x5x5 environment | Watch on YouTube

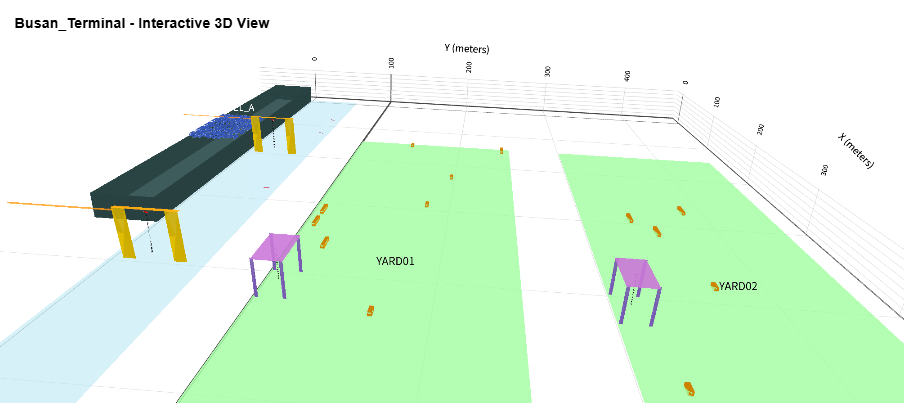

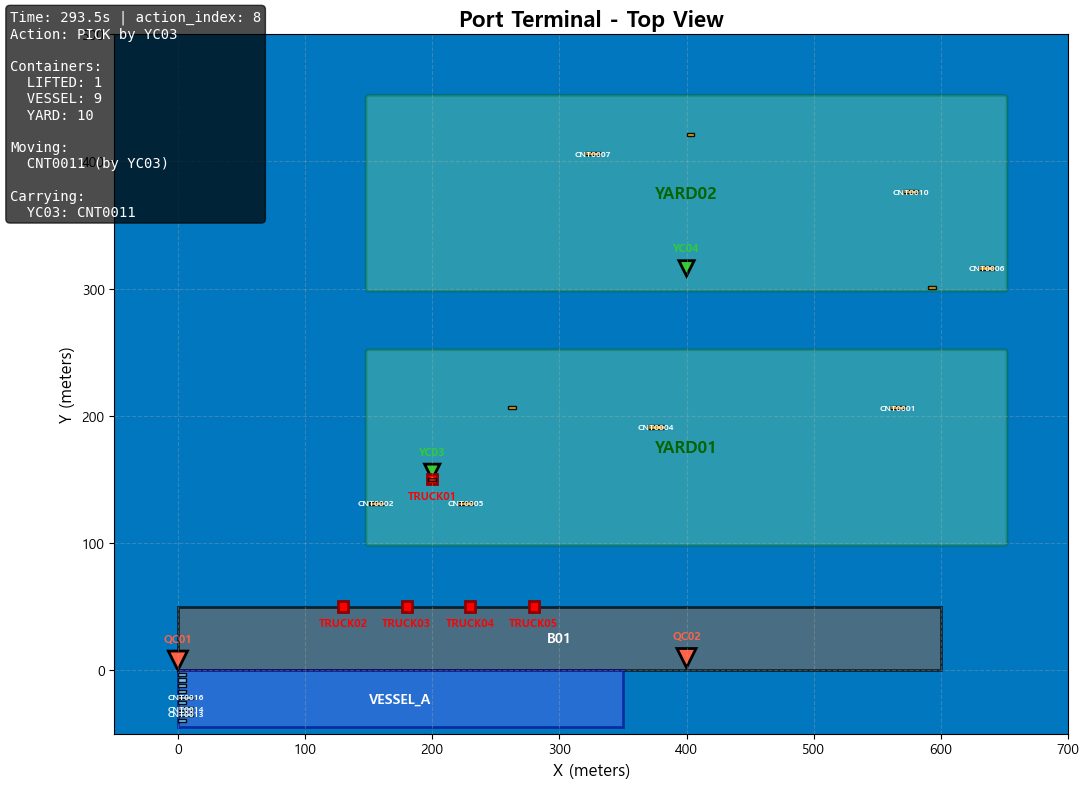

AI Training & Operations Environment. Models complex operational constraints across the entire yard (cranes, ITT scheduling) and continuously trains the T-CAG TYO.

3D Interactive View

Top View (Real-time Status)

T-CAG TYO dramatically reduces rehandling compared to existing Greedy policies.

Immediate OPEX savings and Terminal CAPA increase.

Building on T-CAG's success, MaeBara completes the ultimate vision spanning the entire logistics system.

Core Port Optimization (Rehandle Minimum) technology for OPEX reduction.

CURRENTT-CAG data-driven SCM Efficiency and Global Demand Forecasting.

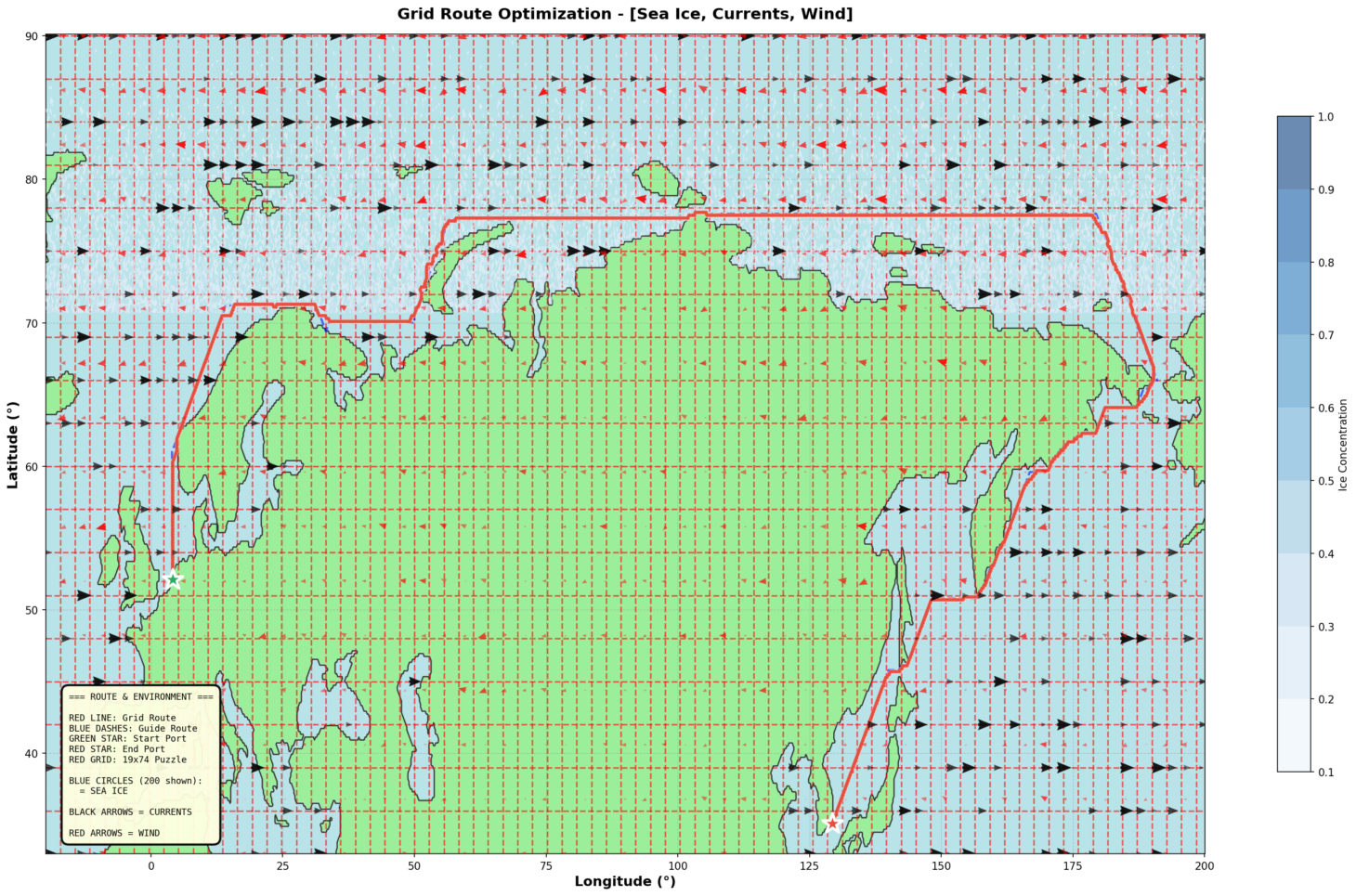

DRL-based Arctic Route & Maritime Economic Routing system.

DRL Agent training environment proven with 459.3 km route reduction in extreme Arctic conditions

MaeBara's DRL technology has already been validated in the most challenging environment (route optimization). This proven capability powers the T-CAG Platform's superior performance.

MaeBara's vision for maritime logistics goes beyond simple efficiency improvement - it aims to set the standard for 'Intelligent Infrastructure'.

We release Technical White Paper v1.0.0, containing MaeBara's core technologies and empirical data to solve the ~500 billion KRW annual operational inefficiency at Busan Port and seize leadership in the upcoming Northern Sea Route era.

See how the overwhelming technical capability proven by OpenAI Hackathon victory solves real industry challenges.

Transform your terminal operations with MaeBara's T-CAG technology.

Email: hansd410@gmail.com | Phone: (+82) 10-3331-8745

Scan QR code to access MaeBara homepage

We support digital transformation across all industries backed by MaeBara's proven expertise.

From planning to launch and operations — Your business partner, MaeBara Labs